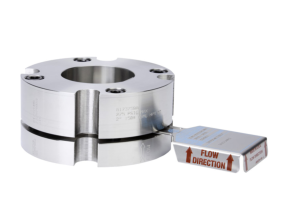

The RHI Holder is a flat seat rupture disc holder which provides improved rupture disc sealing capabilities. The minimal overall height of the RHI Holder allows installation in tight piping arrangements, and retrofit into many existing installations.

The RHI Holder is a flat seat rupture disc holder which provides improved rupture disc sealing capabilities. The minimal overall height of the RHI Holder allows installation in tight piping arrangements, and retrofit into many existing installations.

Flat Seat Holder Features include:

- Available in standard sizes from 1″ through 8″ (25mm – 200mm)

- Available in standard pressure classes from 150# through 600# ANSI (PN 10/16 – PN 40 DIN)

- Standard materials of 316 Stainless Steel, Carbon Steel, Monel, and Hastelloy

- Alignment pins, which provide positive rupture disc orientation

- J-Hook, as standard, to insure positive holder orientation in the system

- Tapered flat seat design, for a positive seal

- Designed to accommodate MICRO X and Composite (FS) rupture discs

- Holder can accommodate a 1/4″ gauge tap in the outlet. Larger taps are optional with an increase in outlet height

- Tested performance; the RHI design has been extensively tested in our ASME-Accepted Flow Test Laboratory, and proven not to leak

- Design allows retrofit into many existing installations, without concern for assembly height

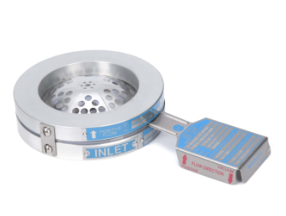

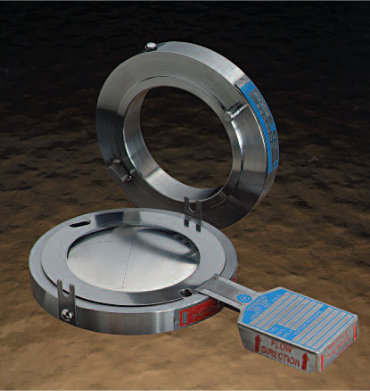

The RHI Holder is available in a wide range of sizes and materials, and is designed to house either the MICRO X Rupture Disc (shown above) or the Composite Flat Seat Rupture Disc.

These non-fragmenting designed rupture discs provide a wide choice of burst ratings, from the low pressures of the Composite Rupture Disc through the higher pressures of the scored MICRO X Rupture Disc.

Application Flexibility- In the event that there is a change in system operating requirements, the flexibility of the RHI Assembly permits utilization of various rupture disc types in order to meet a wide range of burst pressures. The Composite Flat Seat Rupture Disc may be selected for handling very low burst pressures (down to 3 psig / 0,20 barg, depending on size), and the MICRO X Rupture Disc can be utilized for higher pressures (up to 3600 psig / 248,28 barg, depending on size). Thus, the type of rupture disc can be changed, rather than replacing the existing holder.

At Assentech Sales Limited, we offer one of the broadest product ranges of pressure relief bursting discs for a variety of process industries Chemical Processing, Pharmaceutical, Bio technologies, Food and Beverages, Petroleum Refining, Gas and Liquid Storage and Handling Systems ….