Flame Arresters

...Flame Arresters in a nutshell

What?

What?

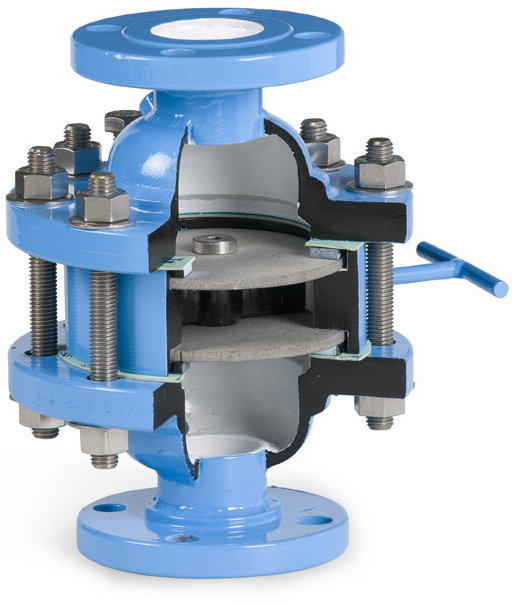

Flame arresters are mechanical devices which allow the flow of air or fluid but prevent a flame from travelling through them. They are installed to stop flame paths travelling along pipes (in-line) and into vessels (end-of-line) and essentially performs two duties. Firstly, they squeeze the oxygen out of a flame to extinguish it and secondly, they cool the flame below its auto ignition temperature.

Why?

A flame arrester limits the damage caused by ignition. They can prevent a fire travelling from one part of a site to another and they can prevent a flame from entering a vessel and igniting vapour.

Where?

Anywhere where there are flammable liquids and gases, from fuel terminals to chemical plants, distilleries and pharmaceutical plants.

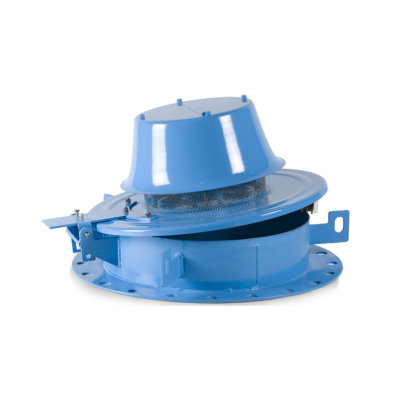

Flame arresters are designed to inhibit flame propagation in gas piping systems and to protect low pressure tanks containing flammable liquids. Arresters protect low flash point liquids from external sources of heat and ignition, increasing fire protection and safety. There are two types of flame arrester technologies: the Deflagration arrester and the Detonation arrester.

Deflagration or Detonation Flame Arresters ?

End-of-Line or In-Line Flame Arresters?

Below is an explanation of the differences between End-of-Line and In-Line Flame Arrester products.

ISO 16852 section 3.21 End-of-Line Flame Arrester – Flame arrester that is fitted with one pipe connection only

ISO 16852 section 3.22 In-Line Flame Arrester – Flame arrester that is fitted with two pipe connections, one on each side of the flame arrester

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.