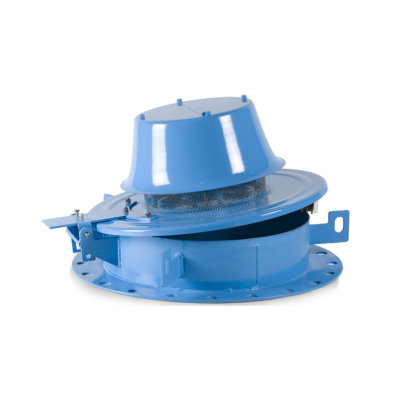

Breather Valves Service and Calibration

Assentech specialises in servicing and calibrating all brands of breather valves in accordance with API 2000 and ISO 28300 which includes the leak test.

As most service providers do not have the specialist equipment to perform leakage testing, this is often a critical step that is missed out. Insufficient knowledge of the industry standards; API2000, ISO28300 and EEMUA 231 also contributes to inadequate servicing and testing.

Why Choose Assentech?

• Protego Authorised Repair Centre (PARC)and Groth Authorised Repair Dealer (GARD) meaning we have access to the full range of workshop manuals and factory support.

• Expertise to test and overhaul breather vents from all other manufactures.

• Comprehensive range of Standard Operating Procedures to ensure consistency and quality.

• Innovator of a calibrated automated test bench to functionally test breather vents either onsite or at our workshop facilities.

• Factory trained service engineers.

• Access to OEM parts.

• We can provide non OEM parts for obsolete models, all of these are manufactured by a ISO 9001 registered company.

• We can offer full traceability of all parts.

WE are more than a Service Company – Here’s Why ….

• Individual leak tests and calibration certificates to International Standards

• Written scheme of examination that will satisfy the Regulators.

• Mechanical integrity review which identifies incompatible materials in the process.

• Supporting a preventative maintenance programme.

• Technical support for failure mode analysis – diagnose key issues with your tank.

• Best practice advice.

• Professional assistance in the management of aging plant.

• Asset registering.

• Tank venting diagnosis

• Technical review of equipment suitability.

• Optimisation of tank venting efficiency.

• Your independent mechanical integrity assessor.

• On-going mechanical equipment suitability assessment.

• Technical Review of obsolete equipment.

Key Benefits

• Demonstrates your due diligence and duty of care to employees, the environment and the investors.

• Tightening of Corporate Governance

• Odour Abatement.

• Supports Ecological Investors.

• Improved profitability through retention of stored product quality.

• Evidential improvement in Environmental ISO 14001 and Health and Safety ISO 45001.

• Noise Reduction through optimisation of tank venting capacity

• Leak detection and reduction in nitrogen consumption on blanketed tanks.

• Reduction in stored product deflagration.

• Reduction in tank corrosion.

• Extension of PVRV lifespan and associated equipment.

• Reduction in plant downtime and unplanned outage.

• Safeguard against enforcement notices or compliance breach

• Evidential reduction in Annual Emissions Statement.

• DSEAR Compliance – reduction of flammable gas clouds.

• Demonstrates full compliance for reduced insurance premiums.

• Occupation Health improvement with reduction of emissions or poisonous vapours.

• Resolution of tank vent failure issues.

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.