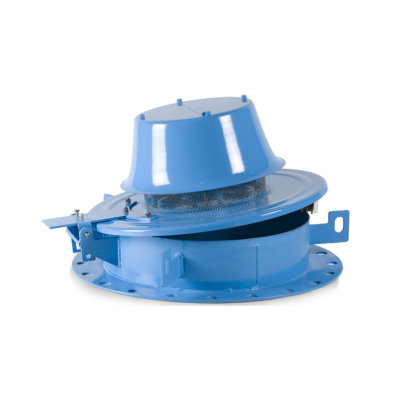

Emergency Relief Vents

The Groth 6000 and 2000 series range of Emergency Relief Valves are designed to provide emergency relief capacity over and above that provided by the normal operating pressure relief valve on the tank. The ERV protects the tank against rupture or explosion which can result from excessive internal pressures caused by an external fire.

Groth offer vertical lift (blow-off) type ERVs, as well as a hinged version which reseats itself and a spring-loaded version which can be offered for high set pressures.

Spring/Weight Operated Emergency Relief Vents

Key Features of the Groth Emergency Relief Vent include;

Key Features of the Groth Emergency Relief Vent include;

- Blow-off and Self Seating options

- Market-leading sealing performance – air cushion seat design creates a superior seal and is less prone to sticking than o-ring type seals

- Self Draining Pallets prevent build-up of water and potential to freeze shut/open

- There are no elastomers in Groth valves as they break down over time in common applications

- Construction in a broad range of materials including FRP

As with all Groth equipment, their ERV’s are manufactured to the highest standards and offer market-leading performance and longevity.

Groth ERV’s come with a range of standard and custom options as follows;

| Models | |

| Sizes | 16”, 20”, 24” |

| Pressure Setting | 6.5 mbar (0.0065 bar) to 1035 mbar (1.035 bar) |

| Operation | Weight Loaded (Hinged |

| Weight Loaded (Vertical lift) | |

| Spring Loaded | |

| Mounting Orientation | Top Mount |

| Materials of Construction | Carbon Steel |

| Stainless Steel | |

| Aluminium | |

| Derakane (FRP) | |

| Furan (FRP) | |

| Exotics on request | |

| Approvals | ATEX |

Pilot-Operated Emergency Relief Valves (PORV)

The Groth Model 2500A pilot-operated Emergency Relief Valve is designed to be self-closing – as excessive pressure builds up it relieves, then automatically reseats when overpressure has been dissipated.

The Groth Model 2500A pilot-operated Emergency Relief Valve is designed to be self-closing – as excessive pressure builds up it relieves, then automatically reseats when overpressure has been dissipated.

Key Features of the Groth Pilot Operated Emergency Relief Vent include;

Key Features of the Groth Pilot Operated Pressure Relief Valve include;

- Documented compliance to EPA’s Method 21 testing (<500 ppm leakage at 90% of set pressure)

- ANSI 150# and API 650 drilling

- Full relief by 20% overpressure

- Trim available in 316 SS or Hastelloy C

- Designed to assist in meeting the requirements of the 1990 Clean Air Act Amendments as best available control technology.

- Provides the capability to meet the leakage rate requirement of 500 ppm or less. A pilot-operated valve with large actuator is the only proven way to ensure the necessary sealing force to meet the requirement.

- Built of corrosion-resistant materials throughout which allows it to be used in severe service environments such as with ethylene dichloride and methylene chloride.

As with all Groth equipment, their Pilot Operated Emergency Relief valves are manufactured to the highest standards and offer market-leading performance and longevity.

| Models | 2500 Series |

| Sizes | 16”, 20”, 24” |

| Pressure Setting | 5” WC to 6 psig |

| Operation | Pilot Operated |

| Mounting Orientation | Top Mount |

| Materials of Construction | Carbon Steel |

| Stainless Steel | |

| Aluminium | |

| Derakane (FRP) | |

| Furan (FRP) | |

| Exotics on request | |

| Approvals | ATEX |

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.