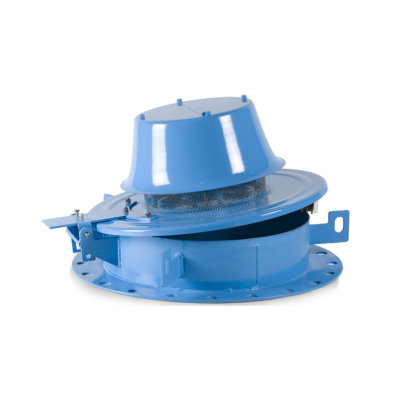

Breather Valves, Conservation vents or Pressure Vacuum Relief Valves (PVRV)

Pressure Vacuum Relief Valves (they are also commonly referred to as breather valves, conservation vents or tank vents) are designed to protect your tank from damage created by over pressure or excessive vacuum.

We at Assentech prefer to use the name “Conservation Vent”, Because the conservation of vapours is a key part of running an efficient and effective storage tank.

Over-pressure or vacuum in a tank can happen because of several reasons like liquid movement into or out of the tank, weather changes, fire exposure and other circumstances resulting from equipment failures or operating errors.

Combined Pressure and Vacuum (PVRV) Relief Valves allow a tank to vent (breathe in and breathe out) during filling, emptying and when thermal effects require.

By using a combined unit, you only require one nozzle and have a single piece of equipment to maintain.

All the relief valves Assentech supply are supplied with leakage and calibration certificates. Leakage testing is now part of ISO 28300 & API 2000. Most manufacturers supply only calibration certificates (not including the leakage tests) which are now technically in contravention of ISO 28300 & API 2000. Testing each vent takes a minimum of 1 hour at the factory and is not something most manufacturers include with every vent. It is usually a cost adder option but we at Assentech include it in our basic price.

Pressure Vacuum Relief Valve 1800 - Full Lift Pressure / Vacuum Relief Valve

The most notable advantage of the Groth Full Lift Type Valve Compared to Standard Pressure/Vacuum Relief Valves is its’ ability to open at overpressure while standard Pressure/Vacuum Relief Valves achieve full open capacity at 100% overpressure. The use of a Full Lift Type Valve allows the user to select the valve set pressure (vacuum) within 10% of the tank Maximum Allowable Working Pressure (vacuum). This is important because operation near the tank design pressure greatly reduces the breathing losses of the product in the tank.

The most notable advantage of the Groth Full Lift Type Valve Compared to Standard Pressure/Vacuum Relief Valves is its’ ability to open at overpressure while standard Pressure/Vacuum Relief Valves achieve full open capacity at 100% overpressure. The use of a Full Lift Type Valve allows the user to select the valve set pressure (vacuum) within 10% of the tank Maximum Allowable Working Pressure (vacuum). This is important because operation near the tank design pressure greatly reduces the breathing losses of the product in the tank.

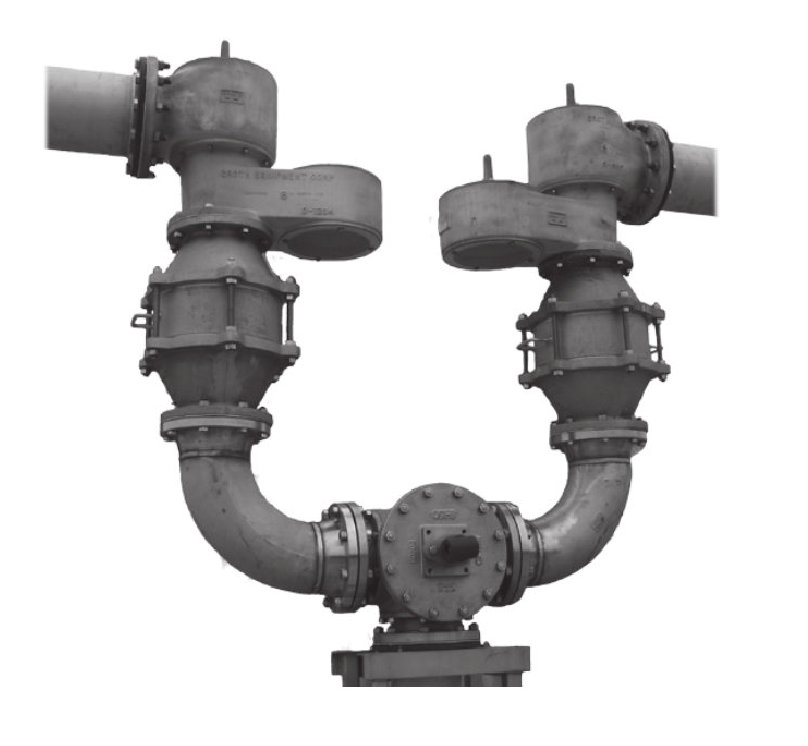

Pressure Vacuum Relief Valves 1220a - With Pipe – Away Feature

Model 1220A is used for pressure and vacuum relief where vapours must be piped away. Escaping vapours are piped away through a flanged outlet connection. This helps to provide increased fire protection and safety.

Model 1220A is used for pressure and vacuum relief where vapours must be piped away. Escaping vapours are piped away through a flanged outlet connection. This helps to provide increased fire protection and safety.

Pressure Vacuum Relief Valves Model 8800a With Flame Arrester

The Model 8800A Pressure Vacuum Relief Valve and Flame Arrester combination units are designed to protect your tank from damage created by overpressure or excessive vacuum, at the same time that they provide protection from externally caused sources of heat and ignition. The result is increased fire protection and safety.

The Model 8800A Pressure Vacuum Relief Valve and Flame Arrester combination units are designed to protect your tank from damage created by overpressure or excessive vacuum, at the same time that they provide protection from externally caused sources of heat and ignition. The result is increased fire protection and safety.

Pressure Vacuum Relief Valves Model 1200

Model 1200A is designed to protect your tank from damage created by overpressure or excessive vacuum. Costly product evaporation losses due to normal tank “breathing” are greatly reduced. Because the Model 1200A retains toxic vapours, atmospheric contamination is minimized. This helps to provide increased fire protection and safety.

Model 1200A is designed to protect your tank from damage created by overpressure or excessive vacuum. Costly product evaporation losses due to normal tank “breathing” are greatly reduced. Because the Model 1200A retains toxic vapours, atmospheric contamination is minimized. This helps to provide increased fire protection and safety.

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.