DTL Vapour Recovery System – Oil & Petrochemical Products

The 3-bed technology has been invented for the purpose of saving energy by utilising equalisation from one adsorber vessel to another adsorber vessel. 20% of the energy usage in a pressure swing Vapour Recovery unit VRU, is spent by the vacuum system on evacuating the adsorber vessels from atmospheric pressure down to 50% vacuum. Adding a third adsorber vessel makes it possible to have one carbon bed on-stream and receive VOC vapour, while the two other beds are in regeneration mode.

VOCZero has refined the “3-bed technology” and built the so-called Adsorber to Adsorber Equalisation (ATAE) operation principle into its advanced range of DTL Vapour Recovery units VRUs, based on a system with only 2 carbon beds.

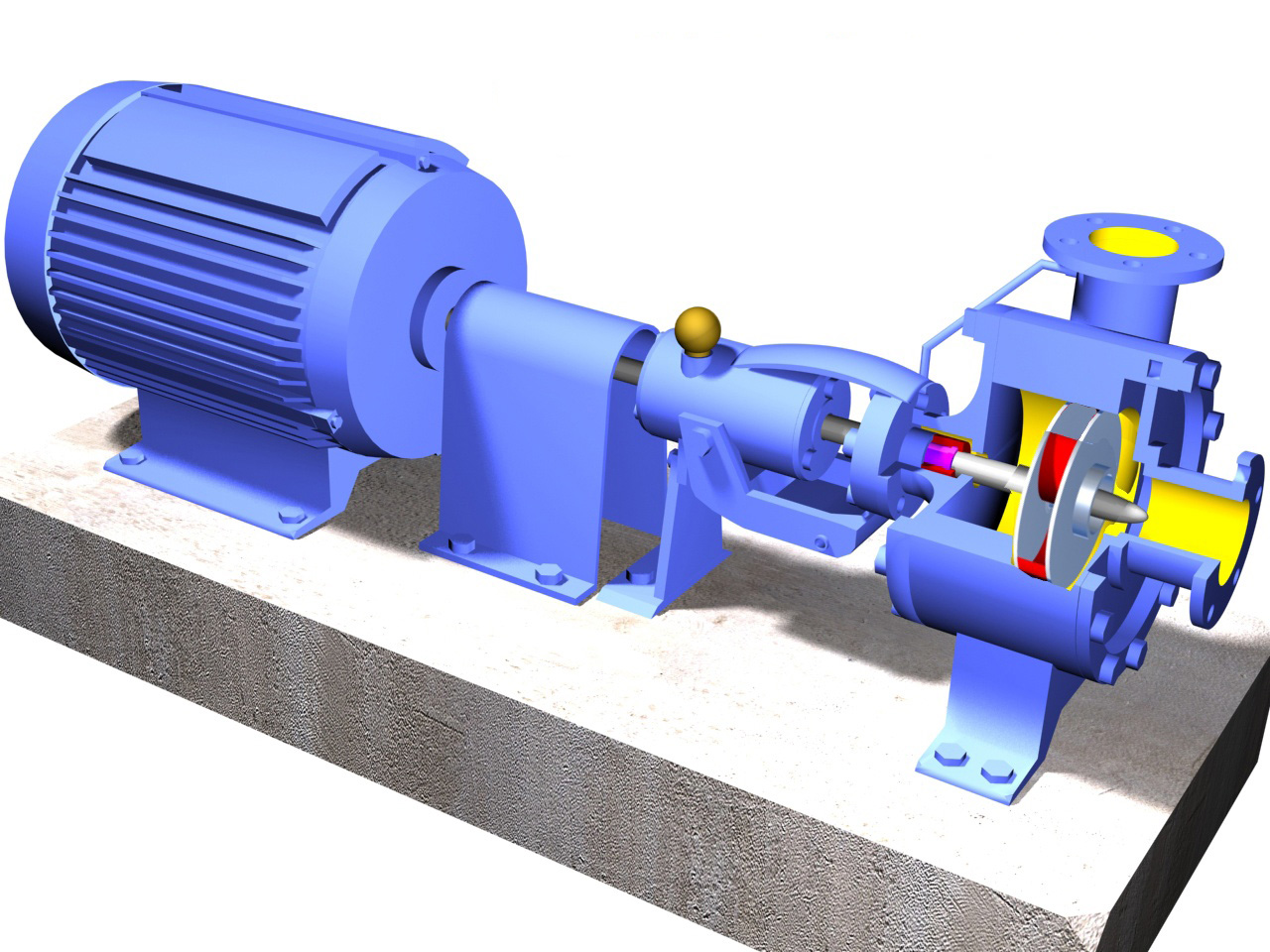

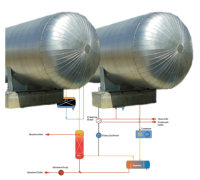

The DTL Vapour Recovery unit is a pre-engineered range of VRUs, covering the vapour recovery needs in terminals from one to fourteen loading racks or nominal VOC vapour capacities from 100 to 6,000 m3/h, in one module. The DTL VRUs are based on VOC adsorption onto activated carbon, and pressure swing regenerated by vacuum.

For oil distribution terminals, in which VOC vapour may be returned from, the DTL VRUs includes a feature for a very high rate of energy saving, called adsorber to adsorber equalisation (ATAE). 20% of the energy usage in a pressure swing VRU, is spend by the vacuum system on evacuating the adsorber vessels from atmospheric pressure down to 50% vacuum. In the DTL VRUs, the adsorber vessel which has finalised the regeneration of the activated carbon and still is at 90% vacuum, is equalised back to higher pressure from the other adsorber vessel, which is at atmospheric pressure and going into regeneration. The resulting pressure of the two vessels after the equalisation is 45% vacuum.

VOCZero’s standard range of VRUs

| VRU Model | Nominal capacity, m3/h* | Feed vapour flow hydraulic design, m3/h | Absorbent flow, m3/h | Vapour inlet pipe dimension, DN | Absorbent pipe dimension, DN | Total installed rated motor power,kW |

Plot space, approximate,Metres,(L x W) |

|---|---|---|---|---|---|---|---|

| DTL100 | 105 | 400 | 6 | 80 | 40 | 14 | 6 x 3 |

| DTL200 | 1695 | 660 | 10 | 100 | 40 | 25 | 6 x 4 |

| DTL350 | 325 | 1,180 | 23 | 150 | 50 | 46 | 11 x 6 |

| DTL450 | 425 | 1,450 | 23 | 150 | 50 | 46 | 11 x 6 |

| DTL600 | 520 | 2,100 | 31 | 200 | 80 | 52 | 11 x 6 |

| DTL950 | 835 | 2,500 | 47 | 200 | 80 | 79 | 12 x 6.5 |

| DTL1200 | 925 | 2,500 | 47 | 200 | 80 | 79 | 12 x 6.5 |

| DTL1900 | 1,650 | 3,450 | 93 | 250 | 100 | 149 | 15.5 x 6.8 |

| DTL2400 | 1,850 | 3,450 | 93 | 250 | 100 | 149 | 15.5 x 6.8 |

| DTL3200 | 2,700 | 4,650 | 140 | 250 | 150 | 209 | 16 x 8 |

| DTL3800 | 3,000 | 4,650 | 140 | 250 | 150 | 209 | 16 x 8 |

| DTL4200 | 3,600 | 5,850 | 187 | 250 | 150 | 284 | 16 x 9 |

| DTL4800 | 3,950 | 5,850 | 187 | 250 | 150 | 284 | 16 x 9 |

| DTL5600 | 4,225 | 7,300 | 235 | 300 | 200 | 370 | 18 x 9 |

| DTL6400 | 4,950 | 7,300 | 235 | 300 | 200 | 370 | 18 x 9 |

| DTL6800 | 5,450 | 8,700 | 282 | 350 | 200 | 436 | 18 x 9 |

| DTL7600 | 5,950 | 8,700 | 282 | 350 | 200 | 436 | 18 x 9 |

Related…

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.